Consistent Naming conventions

Duplicates removed

Data Governance Process

Accurate Data

Data Audit Process

Seamless Flow of Operations

Master

Data Management

- Improve your operational efficiencies

reports from our customers

Standardized

Master Data

KPIs

How Do

We Achieve This

Requirements & Sample Data

Obtain Sample Master Data sets such as Material, Vendor or Customer Masters with all attributes and various descriptions, list of all categories used, naming conventions and similar. Identify any pre-existing rules and data sets that can be leveraged for data Enrichment. Review, Cleanse, Standardization and Enrichment of the Sample Master Data to showcase how the end result will look like - that is Clean and Standardized Master Data.

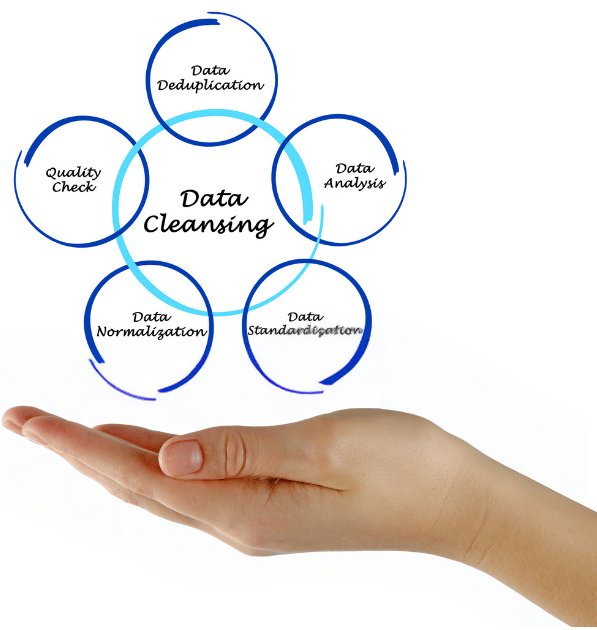

Cleanse And Standardize

Remove duplicates and correct errors using various Master data cleansing tools. Leverage AI and other sources for intelligent data correction and enrichment. Implement consistent naming conventions, formats, and units of measure based on either pre-existing or new rules and standards. Full Review, Cleanse, Standardization and Enrichment of the selected Master Data.

Maintain and Monitor

Establish Procedures and Guidelines for New Data Creation and changes to existing Data sets inclusive of clear Roles and Responsibilities. Implement Data Quality Monitoring systems to track and address issues proactively. Create Master Data KPIs and Reports to consistently maintain high quality of Master Data.

Governance And Training

Develop Audit and Governance framework and procedures with clear Roles and Responsibilities. Set up a system for enforcement of Data Governance Policies and Procedures. Continuously educate staff on the Importance of data quality and accuracy.

partners

Trusted and Supported by Many

Join these Industry Leaders in Getting your Master Data Cleansed, Standardized and under Complete Control with our Innovative Solutions.

Safran

Safran

Siemens

Siemens

Helios

Helios

"Implementing data cleansing and enrichment gave us almost immediate uplift in compliance and data quality."

Maria Lopez Data Manager

"The data standardization process was a game-changer, reducing errors and saving hours of manual work."

John Walters CEO

"Our Master Data is now consistent and standardized and we can rely on it again."

Alex Brown COO

Frequently Asked Questions

Why is Master Data Auditing and Analysis important?

Data Auditing and Analysis helps identify inaccuracies and inconsistencies, allowing for the implementation of standardized naming conventions, formats, and units of measure to ensure uniform data. Combined with Customer Requirements and any other pre-existing data sets it serves as the starting point on a journey of Master Data Cleansing and Standardization.

How do you cleanse, enrich and standardize the Master Data?

We use a number of Automated (including Machine learning algorithms and AI) and Manual (internet, standard parts catalogs, vendor catalogs, customer provided information and similar) cleansing tools to identify and remove duplicate records and correct errors, ensuring data accuracy and consistency.

Data Cleansing and Standardization costs too much and takes too long. Is this going to be cost-effective?

Data Cleansing and Standardization projects don't have to be expensive and take long to be completed. There are many ways to do this to suit different budgets - for example via multi - phase approach. In mid to long-term you will achieve significant cost savings through reduced errors, improved efficiency, seamless flow of data in your ERP system, and fewer resources spent on manual corrections. Additionally you can expect ROI through better Data driven decision-making because the Business will be working with the Data that you can rely on 100%.

How can we see immediate benefits from this investment?

We typically work in a multi-phase approach and aim to achieve quick wins and immediate improvements in data accuracy and operational efficiency very early on in the Project.

What types of Master Data you work with?

We work primarily with Material, Vendor and Customer Master Data. Key services here also include Material classification and categorization using UNSPSC, Eclass or Customer created categories.

Why should we cleanse and standardize our Master Data?

Master data cleansing and standardization is critical for any improvements in data accuracy and reliability, operational efficiencies, and better decision-making. By ensuring consistency across systems and enabling seamless data integration, you can expect to boost customer satisfaction and maintain regulatory compliance. This process also supports robust data governance, reduces costs associated with poor data quality, and provides a competitive advantage through strategic insights. Investing in data cleansing and standardization is essential for maintaining high-quality, dependable business information.

Why do I need Data governance policies and procedures and why are they necessary?

Data governance policies and procedures provide a framework for managing data quality, ensuring compliance with your adopted standards, and assigning responsibilities to data stewards for ongoing oversight. These are essential for ensuring that new data created follows the agreed Standards.

Why is Employee Education and Training important for data quality?

Educating your staff on the importance of Data quality, consistency and accuracy ensures everyone understands the importance of maintaining high data standards and is equipped with best practices and tools for effective data management.

our process

How It

Works

Intro Call and Sample Data Review

Our team will first do a quick call to understand your Business requirements. Then we will conduct a thorough requirements gathering process including some sample data collection related to the Scope. Sample data will then be analyzed, cleansed, enriched, categorized and standardized to get you a clear understanding what you will be getting as final deliverable.

Data Cleansing and Standardization

Once the Client is happy with the Sample data cleanse process, we proceed with the rest of the process. First step is data categorization using UNSPSC, eclass or Client provided taxonomy. This is then followed by Data enrichment using all available information - either publicly available or provided by the Client. Some other steps include review of final naming conventions, list of attributes and similar.

Delivery and Upload of Cleansed Data

At the end of each completed phase of the Project, the Client reviews and signs off on the cleansed, enriched and standardized Data sets confirming they all fully meet the requirements. We also document and provide you with all the logic, naming conventions and standards utilized in the process. Once the Project is completed, we will provide you with the data back to you in the agreed format.

Governance, Procedures and Training

Our standard practice is to provide you with comprehensive training sessions and high-quality training materials for your users including very structured process guides and other documentation but this also depends on the scope of our engagement. With our training, your users will gain the confidence and expertise to maximize the value of our solutions, driving your business forward.

Who We Are

Data

And

Process Experts

Etomix is a dynamic digital consulting agency that offers top-notch services, including business analysis, master data management, spend analytics and procurement savings tracking. Our in-house-built Procurement Savings Tracker Application enables clients to streamline operations and maximize savings. Our team delivers custom-tailored solutions from ideation to execution, exceeding client expectations.

We stay ahead in the fast-paced digital landscape by exploring new technologies and strategies to help clients stay competitive and profitable. Etomix is the trusted partner for optimizing processes, increasing ROI, and enhancing digital presence.